Gunsmithing is a precise art. Your average Joe might be a bit at sea here. The weakest link in a shooting system is the connection of the riflescope whether the long-range or the hunting or the rimfire or the thermal scope to the firearm.

Scope mounts, rings, and bases make up this connection and unless these are fitted to a high degree of precision, even your high-end scope and rifle combination is pretty useless.

In this article, we endeavor to methodically explain how to lap scope rings, an integral lesson for the health of your scope and for accurate shooting.

What Is Lapping?

The procedure of lapping in layman’s lingo is taking two or more surfaces, putting on some sort of abrasive compound between them, and generating friction between the parts.

The desire is to smoothen and polish the surfaces and the process profiles the surfaces so they fit together better.

Lapping increases the surface contact between the scope tube and ring and aligns the scope rings. So how is it done?

The base and rings are assembled on a steel lapping bar, and the abrasive compound, silicon carbide, aluminum oxide or alumina, and boron carbide being commonly used, is coated on the bar.

The rings are tightened until the bar can move with resistance.

The bar is then worked back and forth. The bar in conjunction with the compound knocks off the high spots and uneven patches polishing the ring surface in contact with the bar.

Lapping is a sound practice that increases the performance of some kinds of mounts, especially windage-adjustable ones.

Getting a professional to do the job of lapping scope rings will cost you an arm and a leg. DIY is the answer to get going, buy a Scope Rings Align Lapping Kit.

It’ll set you back by about $70 which is a cheap way to get the job done and also learn firsthand about your prized rifle.

How to Lap Scope Rings: DIY Scope Ring Lapping Guide

Things Needed for The Job

- Scope Ring Lapping Kit

- Allen key, most probably provided for your rings by the manufacturer

- Polishing compound

- Paper towels

- Marker pen to label the ring sections

- Screwdrivers

Scope Rings and Ring Height

Measure the diameter of the scope body at the objective lens end and divide that figure by 2.

That is the scope height. Ring height varies from one manufacturer to the other. That is because of the method of measurement as shown above.

Ring heights range from 26mm, 30mm, 34mm, etc. in incremental steps of 4mm.

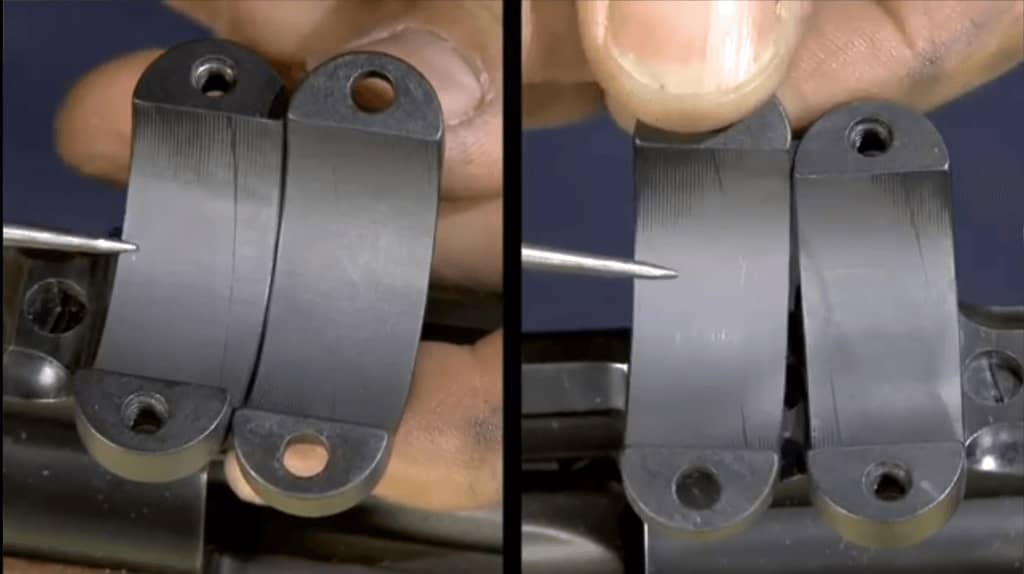

Vertically split rings offer greater contact.

Positioning The Scope

It is very important that the scope is stable while doing the lapping.

You will require a padded bench fly to anchor the barrel of your rifle firmly. A perfectly placed rifle scope will enhance your shooting experience to a great extent.

Checking The Alignment

- Position the scope rings in place.

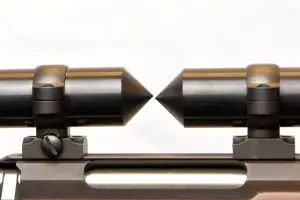

- The alignment bar goes into the rings, tips not touching but nearly.

- Secure the alignment bar to the top rings and screw tight.

Aligned

Out of alignment

Marking The Rings

Do not mix up the rings after lapping is completed. Mark them However you feel convenient.

Don’t even reverse them, left for a right or vice versa. They must be put back exactly in the same position.

Using The Lapping Bar

1. Remove the alignment bar. We are ready to embark on the exercise of lapping the scope rings.

2. Coat the rings and lapping bar with the polishing compound.

3. Now we fit the lapping bar, or as some call it, the lapping tool.

4. Put back the top half of the rings and tighten them. An important consideration here is not to tighten the rings too tightly or you may damage the rings. The lapping bar should offer very slight resistance only.

5. Move the lapping bar forward and backward about 30 times. You can feel the motion easing smoother. Then tighten the holding screws at the top of the rings a little, and continue moving the bar.

A 100% contact with the lapping bar is an impossibility. About 80% is achievable which is sufficient for flawless alignment of the scope.

The Moment Of Truth

Take off the rings completely. Feel with your fingers the change in the smoothness.

Cleaning The Rings

Using a water spray, clean the rings thoroughly to get rid of compound remnants and lapping debris. Dry with a paper towel.

Congratulations! Now you know how to properly lap scope rings and you’re ready for some action. Your lapped scope rings are as good as new with proper holding power due to increased contact.

How to Lap Scope Rings: Pro Tips for Perfect Alignment

- Even if your scope is newly purchased, the rings are seldom machined properly.

- Before cleaning with water, using a paper towel, clean off the rings.

- Don’t do a rush job on the cleaning after completing the lapping. It could lead to problems next time around

- Rings that are not aligned will exert a force on the rifle scope distorting it Now that you have a scope lapping kit, you can check the alignment every once in a while.

- Measure the scope height and adjust it to ensure compatibility with the lens and rings.

- A bent scope plays havoc with accuracy as the barrel is also affected by the scope’s distortion.

- Using light grease, coat your alignment tools, wrap them in a clean cloth and keep it in a safe, dry location for next time.

Our night soldier is on the prowl with his refurbished, trusty riflescope!

No quarry is safe. Now that you have the complete roadmap of lapping scope rings the right way, remember that it’ll keep your scope secure.

Most manufacturers claim that their design is unique and tested. You will need to make certain that scratches are not being inflicted on your scope by the contact.

The entire process takes under 30 minutes, and the reward is a completely scratch-proof scope.

FAQs

Do You Need to Lap Scope Rings?

Technically, no. Scope rings are designed to securely mount a scope onto a rifle without the need for lapping. However, there are some instances where it may be beneficial to lap scope rings in order to get the most secure and accurate mount possible.

How Far Apart Should Scope Rings Be Mounted?

Generally, a maximum gap of 0.35 inches between two scope rings is recommended. However, this can vary depending on the size of the scope and the type of rifle you are using. The most common advice is to mount the scope rings as far apart as possible while still maintaining a secure fit.

How High Should You Mount a Scope?

The general rule of thumb for mounting a scope is to keep it as low as possible. This allows for better eye relief and also helps reduce the amount of recoil felt by the shooter. Generally, it is best to mount the scope so that its center line sits 1-2 inches above the centerline of the bore.

Leave a Comment