Both the M4 and the S90V are premium quality steels that are widely used across the globe.

From blades to medical equipment, these super-steels provide exceptional durability and performance.

Both of them use a similar material composition and with some minor exceptions, provide similar performance.

The key difference between these two lies in grindability, toughness, corrosion resistance, and price.

The M4 is cheaper, tougher, and easier to sharpen

Find out more in our “S90V vs M4” head-to-head comparison guide!

What is the S90V?

S90V or CPM S90V is a reputed name in the steel industry.

It is one of the supreme quality steels available throughout the US that provides amazing edge retention, exceptional wear resistance, and superb corrosion resistance.

The S90V is made by The US Crucible Industries. The manufacturers use a unique combination of carbon, chromium, and vanadium to make the steel durable, strong, and wear-resistant.

It’s used to make valve components, bearings, slitters, cutters, and knives.

What is the M4?

The M4 AKA the CPM M4 is considered high-speed steel with great versatility. Just like the S90V, the M4 is also produced by US Crucible Industries.

This particular composition uses a lot of alloy metals for superb hardness, toughness, and wear resistance.

Like any other high-speed steel, the M4 has the power to easily cut through any substance.

That’s why it is widely used in making custom knives. The tough and versatile nature helped the M4 to get picked by the medical industry.

S90v vs M4: How They Differ

1. Chemical composition

S90V

The core alloying elements of the CPM S90V are Vanadium, Carbon, and Chromium.

It also contains a trace amount of Manganese, Phosphorous, Molybdenum, Silicon, Sulfur, and Tungsten; among other elements.

These elements provide tensile strength, durability, and machinability. Here is a chart showing the different percentages of alloying elements used in constructing CPM S90V:

| Alloying Element | Percentage (%) | Effect |

| Chromium (Cr) | 14.00 | Improves tensile strength, edge retention, and corrosion/wear resistance |

| Vanadium (V) | 9.00 | Upgrades wear resistance and hardenability |

| Carbon (C) | 2.30 | Increases hardness and wear/corrosion resistance |

| Molybdenum (Mo) | 1.00 | Improves machinability and strength |

| Silicon (Si) | 0.50 | Improves strength |

| Manganese (Mn) | 0.50 | Develops hardness and brittleness |

| Tungsten (W) | 0.40 | Improves wear resistance and hardness |

| Phosphorous (P) | 0.030 | Increases strength |

| Sulfur (S) | 0.030 | Increases strength |

The chemical composition of these two super-steels is similar. The only difference lies in the concentration.

They also produce similar results in performance.

M4

Even if the core alloys used in making M4 are similar to that of the S90V, different concentration allows the steel to be much harder and tougher.

The CPM M4 is a high carbon, high alloy steel. A higher percentage of alloys like Molybdenum and Tungsten helps the steel to be super tough.

Here is a chart showcasing the key alloys used in making the versatile and high-end CPM M4 steel:

| Alloying Element | Percentage (%) | Effect |

| Tungsten (W) | 5.50 | Increases hardness and edge retention |

| Molybdenum (M) | 5.25 | Improves machinability and strength |

| Chromium (Cr) | 4.00 | Develops tensile strength and corrosion resistance |

| Vanadium (V) | 4.00 | Increases wear resistance, toughness, and hardenability |

| Carbon (C) | 1.42 | Increases hardness and edge retention |

| Silicon (Si) | 0.55 | Improves strength |

| Manganese (Mn) | 0.30 | Introduces hardness and brittleness |

| Phosphorus (P) | 0.03 | Develops internal strength and structural integrity |

2. Hardness

S90V

S90V achieves a score of 57-59 HRC on the Rockwell hardness scale, which identifies it as hard (hardened) steel and provides durability to the metal.

The majority of every day and premium-quality knives available today are made from this type of steel.

However, the steel is comparatively softer than the M4.

Additionally, a higher concentration of Vanadium makes the S90V a little less machinable.

M4

The M4 contains a lot of carbon and that increases the hardness of the steel. It has a score of 65 HRC on the Rockwell hardness scale, which is harder than most other steels.

This additional hardness helps the M4 to be a viable option in making medical equipment, mechanical parts, and knives.

M4-made knives usually showcase high resistance to surface deformation, penetration, and even scratching. That’s why it has become a fairly popular knife material.

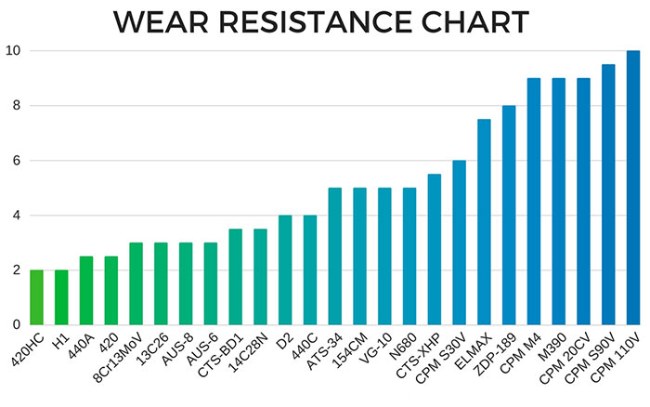

3. Wear resistance

S90V

This super steel features exceptional abrasion and corrosion resistance.

The high volume of Vanadium alloy produces super-strong vanadium carbides, which significantly improve the wear resistance.

As a result, CPM S90V knives can tackle a lot of rough uses effortlessly over a long time.

M4

A higher concentration of Tungsten, Chromium, Molybdenum, and Vanadium helps the M4 to outgrow even the S90V in terms of hardness and wear resistance.

Knives made from the CPM M4 high-speed steel are exceptionally good at edge retention and toughness.

Unlike the knives made from the S90V, M4 blades are easier to sharpen but harder to wear or damage.

That’s why it’s becoming increasingly popular among knife enthusiasts.

4. Edge retention

S90V

CPM S90V also features a perfect balance between Vanadium and Chromium to introduce almost perfect edge retention.

The steel even has the capability to outperform other top-quality steels like D2 and S30V.

The superior edge retention capability of the S90V takes it to the top of its class. Whether you use S90V steel for light or heavy-duty work, you won’t be disappointed.

M4

The performance of the mighty M4 dwarfs even some advance-grade steels like the S30V, D2, and CPM 154; which are known for their exceptional edge retention.

This premium steel offers some of the best edge retention possible. That’s why the M4 is widely used in medical equipment, tools, and components.

5. Toughness

S90V

In the journey to achieve supreme quality edge retention and high hardness, the steel had to compromise on toughness.

The S90V provides toughness similar to the D2 steel but falls behind steel like S35VN and S30VN.

Despite being hard, the CPM S90V is a bit fragile.

However, it takes a lot of rough uses to get the S90V steel blade chippy, cracked, or broken.

M4

Without compromising either, the CPM M4 managed to achieve both toughness and hardness through the right combination of alloys.

However, it paid the price in corrosion resistance.

As a result, the M4 steel provides excellent performance in both toughness and hardness, meaning your blades will last you a long time without any significant reduction in performance.

6. Grindability

S90V

The superior toughness and strength of the S90V don’t come for free.

The steel is really tough. That means just as it would last a long time, it would also be a huge pain to grind and sharpen.

The vanadium carbide produced in the S90V is even tougher than chromium carbide.

As a result, you won’t be able to sharpen your S90V blades with traditional aluminum oxide abrasives and sharpening stones. You’ll need a diamond or CBN stone for that.

The bad news is you’ll need to invest much of your time and effort to sharpen the blade; and the good news is, you won’t need to do that very often.

M4

Here, The CPM M4 takes the cake with ease. Despite being super tough and hard, the steel is relatively soft to grind and sharpen.

You can sharpen your M4 blade with relatively simple elements like sharp maker brownstone.

Additionally, the superior edge retention will make sure that you don’t need to sharpen your blades every now and then.

7. Corrosion resistance

S90V

This rust-proof and corrosion-resistant metal use a high concentration of Chromium in its composition, which makes the steel durable and versatile.

They can be used in a wide range of tools and components.

That’s why S90V-made knives are commonly known as “The one for all steel knives” among knife enthusiasts.

Vanadium also helps to improve corrosion resistance by forming Vanadium carbide.

M4

This is one of the biggest disadvantages the M4 has over its competition.

Even if the high-speed M4 steel offers a decent amount of wear resistance, it lags behind in corrosion resistance.

The steel isn’t stainless. It’ll take a little effort from your side to keep the steel going for a long time.

You can either apply an anti-corrosion finish or maintain your blades regularly to make sure your blades work for a long time.

8. Price

S90V

The price greatly depends on the quality of the material and the dimension of the steel bar.

Using a higher number of alloys to reinforce the S90V increases the overall cost. You can get a decent quality S90V knife for around $120 – $950.

M4

This round goes to the M4 as well. With a relatively cheaper alloy composition, the CPM M4 is able to provide extreme performance within an affordable price range.

A good quality M4 blade can cost you $120 – $400 on average. Custom-made blades, however, will cost significantly more.

S90V Vs M4: Which one to choose?

It’s a bit tricky to answer because, both the CPM S90V and the M4 offer similar performance in wear resistance and edge retention.

They both use similar alloy compositions and are widely popular across the globe.

The only deciding factor in today’s head-to-head comparison is the price.

The M4 has a slight edge over the hardness and the grindability whereas the S90V stands out in toughness and anti-corrosion properties.

As a result, it comes down to your personal preference.

If you can’t put your time and effort into sharpening your blade once in a blue moon, want a cheaper alternative, and are interested in improving your honing skills, the CPM M4 is the best choice for you.

On the contrary, if you want a blade that will last you a lifetime and won’t require much attention, go with the CPM S90V. It’s worth the extra penny.

FAQs

1. Is M4 Good Steel For Knives?

Ans: Yes, of course. The CPM M4 is one of the best quality steels available for knives.

The easy grindability; combined with superior edge holding, extreme sharpness, exceptional toughness, and affordability make the steel a perfect material for your blade.

Leave a Comment