Both the S90V and the 20CV are considered super steels and their main difference lies in their material composition.

The S90V uses a wider range of alloys for the best performance whereas the 20CV is a bit cheaper and doesn’t perform as well as the S90V.

Let’s explore more information in our in-depth “S90V vs 20CV” premium steel comparison!

What is S90V?

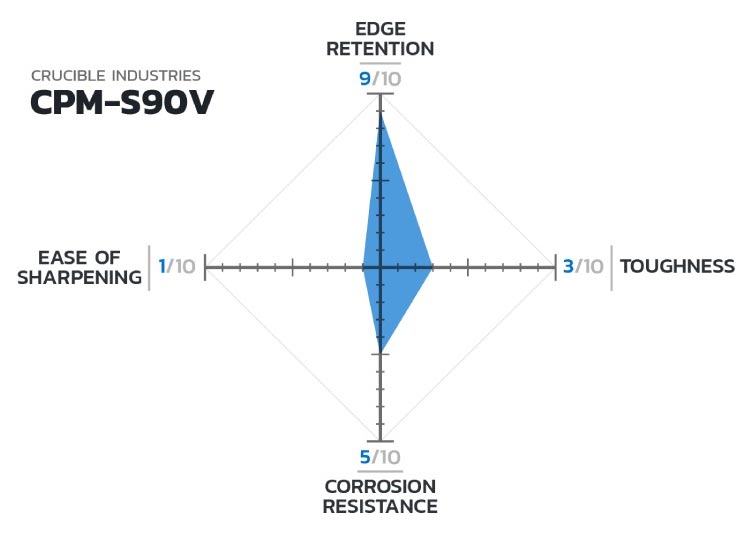

Also known as the CPM S90V, this premium quality steel is widely famous for its impeccable edge retention, supreme wear resistance, and high corrosion resistance.

The steel is produced by US-based Crucible Industries and is a part of the Crucible SxxV series.

This high-end steel is rated as one of the best super steels available today.

A high concentration of carbon, chromium, and vanadium makes the steel super strong, durable, and wear-resistant.

S90V is usually used to make valve components, slitters, bearings, and of course, knives.

What is 20CV?

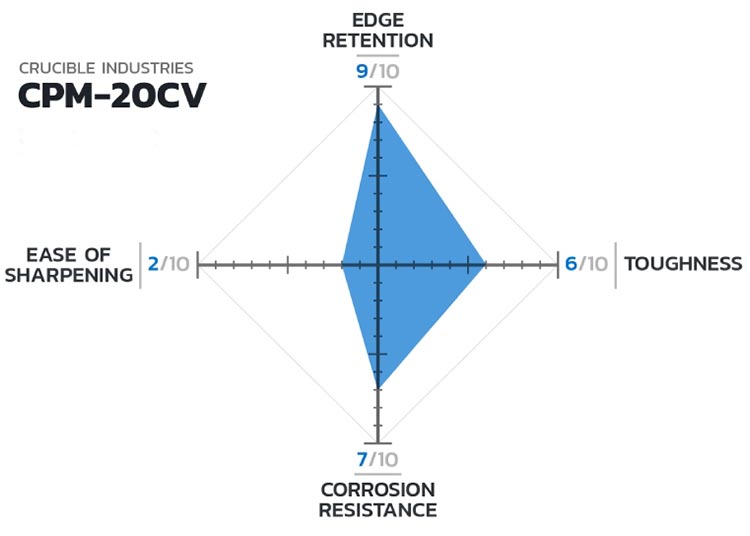

The 20CV is also a grade of stainless steel produced by US-based Crucible Industries using a special method named Crucible Powder Metallurgy (CPM).

That’s why the steel is also known as CPM 20CV. The CPM technology upgrades the toughness and grindability of this steel.

20CV is also considered one of the super steels as it has the highest amount of chromium and a lot of vanadium carbides, providing exceptional corrosion and wear resistance.

Due to the CPM process, the steel has a finer and more even carbide distribution than its other counterparts.

S90v vs 20cv: What’s the Difference?

1. Chemical composition

S90V

The CPM S90V has carbon, vanadium, and chromium as its core alloying elements.

It also contains materials like Manganese, Molybdenum, Silicon, Sulfur, Phosphorous, and tungsten; among other elements.

All these elements provide toughness, durability, and machinability. Here is a chart showing the different percentages of alloying elements used in constructing CPM S90V:

| Alloying Element | Percentage (%) | Effect |

| Chromium (Cr) | 14.00 | Improves tensile strength, edge retention, and corrosion/wear resistance |

| Vanadium (V) | 9.00 | Upgrades wear resistance and hardenability |

| Carbon (C) | 2.30 | Increases hardness and wear/corrosion resistance |

| Molybdenum (Mo) | 1.00 | Improves machinability and strength |

| Silicon (Si) | 0.50 | Increases strength |

| Manganese (Mn) | 0.50 | Develops hardness and brittleness |

| Tungsten (W) | 0.40 | Improves wear resistance and hardness |

| Phosphorous (P) | 0.030 | Increases strength |

| Sulfur (S) | 0.030 | Increases strength |

20CV

The CPM 20CV is known to have the highest concentration of chromium (20%) among all stainless steel grades.

The high chromium concentration makes this steel exceptionally good at anti-corrosion.

This steel also contains a trace amount of Molybdenum, Vanadium, and Tungsten. Here are what the percentages of elements used to make CPM 20CV look like

| Alloying Element | Percentage (%) | Effect |

| Chromium (Cr) | 20.00 | Improves tensile strength, edge retention, and corrosion/wear resistance |

| Vanadium (V) | 4.00 | Upgrades wear resistance and hardenability |

| Carbon (C) | 1.90 | Increases hardness and wear/corrosion resistance |

| Molybdenum (Mo) | 1.00 | Improves machinability and strength |

| Tungsten (W) | 0.60 | Develop wear resistance and hardness |

2. Hardness

S90V

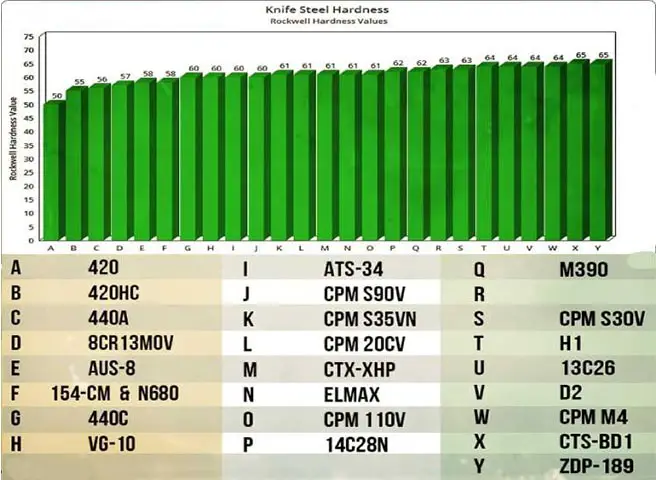

CPM S90V scores 57-59 HRC on the Rockwell hardness scale, which is above the softer steels and provides durability to the metal.

Most everyday carry and premium-quality knives are made from this type of steel. However, the higher Vanadium count makes it a little less machinable.

20CV

The higher concentration of Chromium gives the CPM 20CV a slight advantage and a better ranking on the Rockwell hardness scale (58-61 HRC).

This results in a superb quality metal that is perfect for making high-quality knives. Knives made from this steel are tough and durable.

3. Wear resistance

S90V

Exceptional wear and abrasion resistance are one of the key features of the S90V stainless steel.

The higher volume of Vanadium used in the process creates super-strong vanadium carbides, significantly improving the wear resistance.

As a result, knives made from CPM S90V can withstand a lot of rough uses over a long time.

20CV

The CPM 20CV uses a comparatively lower concentration of Vanadium than the CPM S90V. As a result, it is comparatively a bit less durable.

However, it’s still strong enough to live through all your rough uses unscathed for a long time.

The 20CV is a bit brittle, which allows the S90V to take the lead.

4. Edge retention

S90V

The S90V takes the cake here as well. A perfect combination of Vanadium and Chromium introduces near-perfect edge retention to all your blades.

The steel even performs better than other top-quality steels like D2 and S30V.

Whether you use your S90V steel knife for light or heavy-duty work, the steel won’t disappoint you.

The superior edge retention capability of the S90V makes the usual steel look like a joke.

20CV

Edge retention refers to the resistance your knife puts up against being dulled by chemical, mechanical and thermal influences.

Elements like Molybdenum and Tungsten provide the 20CV with the necessary strength it needs to withstand your everyday use.

Vanadium also helps here by producing a finer grain structure that is crucial for keeping the edge of your knives intact.

5. Toughness

S90V

Here, the S90V falls behind in the competition between S90v vs 20cv. It provides a decent quality of toughness, which is similar to the D2 steel, and falls behind steels like S35VN and S30VN.

In order to achieve supreme quality edge retention and high hardness, the steel had to compromise on toughness.

As a result, the CPM S90V is a bit brittle. It can withstand some degree of rough use without getting chippy, cracked, or broken.

20CV

The CPM 20CV takes the lead this round and offers great resistance to rough uses like chipping and breaking.

Usually, steels that offer high hardness and exceptional corrosion resistance tend to sacrifice toughness.

The 20CV is an exceptional quality super steel that strikes a perfect balance between hardness and toughness.

This may be true that there are even better steels out there, but the 20CV still provides some amazing results in surviving everyday wear and tear.

6. Sharpenability

S90V

All the toughness and strength of the S90V come at a price and that is, the S90V is really hard to sharpen.

The vanadium carbide in the S90V is even harder than the chromium carbide. A

s a result, traditional aluminum oxide abrasives and sharpening stones can’t sharpen the S90V blades.

If you want to sharpen your blade effortlessly, you might want to get a diamond or CBN stone. Just as the blade is tough to dull, it’s also tough to sharpen.

20CV

With CPM 20CV, the result is similar. The 20CV also sacrifices sharpening ability for toughness.

There is a saying among knife enthusiasts that you need the patience of a saint to sharpen your blades made from these super steels.

The only good news here is that once you sharpen your blade, you can forget about resharpening for a long time.

7. Corrosion Resistance

S90V

This super steel uses around 14% Chromium, which makes it rust-proof and corrosion-resistant.

Many people refer to knives made from S92V as “The one for all steel knives”. The Vanadium used in the process creates Vanadium carbide and improves corrosion resistance.

20CV

The higher Chromium count allows the CPM 20CV to be able to resist oxidation from moisture, humidity, salt, and the environment.

With slightly better corrosion resistance, the 20CV secures the lead here.

8. Price

S90V

Using a higher number of alloys to reinforce the S90V increases the overall cost. The price greatly depends on the dimension of the steel bar and the quality of the material.

You can get your hand on a decent S90V knife for around $120 – $950.

20CV

The 20CV wins again with a comparatively cheaper price range than the S90V.

Despite being cheaper, the 20CV provides outstanding performance that dwarfs the performance of even some higher-class steels.

For a knife made from CPM 20CV, you’ll need to spend about $150-$400.

20CV vs S90V: Which one to choose?

20cv vs s90v? That depends entirely on your personal preference.

Both CPM S90V and CPM 20CV are exceptional quality super steel that offer similar performance in terms of grindability and edge retention.

It’s a real dilemma to choose the best when thinking about S90v vs 20cv.

Each type of steel adds its unique pros and cons to the list.

However, with a slight advantage over price and toughness, today’s winner is CPM 20 super steel. The COM S90V offers better material composition and corrosion resistance.

Feel free to choose whichever seems perfect for your intended work.

If you want better quality at a cheaper price, go for the 20CV; and if you want better construction for heavy work, choose the S90V.

You won’t be disappointed no matter which one you end up choosing.

FAQs

1. Is S90V good steel for knives?

Ans: Yes, the S90V is a supreme quality steel and a perfect choice for making knives.

The steel offers exceptional edge retention, supreme wear resistance, and high corrosion resistance. However, the poor grindability of CPM S90V can be a real pain for many people like me.

2. What’s the toughest steel for knives?

Ans: There’s no “toughest” steel out there because they all have different properties. Some excel in edge retention, some have the highest sharpness level, and some are highly durable.

The stainless CPM-20CV/Bohler M390/CTS-204P (same steel from different brands) has the finest balance of toughness and edge retention.

The S35VN is also tough, easy to sharpen, and great at edge retention while the S90V/S110V is another amazing choice but is chippier than other premium steel because of its high hardness and difficult to sharpen.

3. Is S90V difficult to sharpen?

Ans: Yes, the S90V is really hard to sharpen simply because the steel is resistant to wear. We recommend that you use diamond grit sharpeners for the best results.

Leave a Comment