The M390 is essentially the European equivalent of the US-based CPM 20 CV super steel.

Both the M390 and the 20CV use the same PM (powder metallurgy) technology and offer similar performance in terms of edge retention, grindability, and corrosion resistance.

However, these two super steels differ in toughness, aesthetics, and price.

The M390 tends to be a bit tougher, more aesthetically pleasing, and of course, more expensive than its US counterparts.

Let’s explore more in our in-depth M390 vs 20CV steel comparison guide!

SummaryM390, 20CV, and 204P are all chemically identical steels and made for the same purposes and intents. The only difference will be in how the different manufacturers heat treat these steels.

The M390 – A quick look

M390 is a martensitic, high-vanadium, high-chromium, and stainless super steel manufactured by Bohler-Uddeholm.

According to the manufacturer, the M390 is a “micro-clean” super steel that offers superior edge retention and extraordinary wear/corrosion resistance.

Technically, the M390 is a tool steel, meaning that the steel is well equipped to withstand heavy uses for a long time.

It can achieve a near-perfect mirror finish, giving your blades a cool outlook. The blade is also used to make screws, injection molding, and barrels.

The 20CV – A quick look

The CPM 20CV is also martensitic, premium-grade stainless steel.

Known for its high Chromium and Vanadium count, the steel is manufactured by USA’s Crucible Industries and is widely used to make screw tips, mold cavities, and barrel liners.

The 20CV super steel offers outstanding wear/abrasion resistance and anti-corrosion properties.

This durable steel is known to provide the perfect balance of durability, toughness, and flexibility. That’s why 20CV is widely popular as knife steel across the globe.

M390 Vs 20CV: What’s the difference?

Composition

M390

The M390 is almost identical to the 20CV in terms of material composition. The only difference is the added Manganese and Silicon in the M390.

A high concentration of Chromium gives the steel its toughness whereas the Silicon and Manganese introduce tensile strength.

Here is what the material composition of the M390 steel looks like:

| Material | Concentration (%) | Effect |

| Chromium (Cr) | 20.00 | Increases corrosion resistance and toughness |

| Vanadium (V) | 4.00 | Improves toughness and wear resistance |

| Carbon (C) | 1.90 | Develops tensile strength |

| Molybdenum (Mo) | 1.00 | Improves strength, hardness, and toughness |

| Silicon (S) | 0.70 | Introduces corrosion resistance and strength |

| Tungsten (W) | 0.60 | Develops hardenability and toughness |

| Manganese (Mn) | 0.30 | Elevates tensile strength and hardenability |

20CV

Just like the M390, the CPM 20V also has a high concentration of Chromium and Vanadium, which provides impeccable wear/corrosion resistance.

Both the 20CV and the M390 have the highest concentration of chromium among all the stainless steel grades available today.

Let’s have a look at the material composition of the CPM 20CV super stainless steel:

| Material | Concentration (%) | Effect |

| Chromium (Cr) | 20.00 | Increases corrosion resistance and toughness |

| Vanadium (V) | 4.00 | Improves toughness and wear resistance |

| Carbon (C) | 1.90 | Develops tensile strength |

| Molybdenum (Mo) | 1.00 | Improves strength, hardness, and toughness |

| Tungsten (W) | 0.60 | Develops hardenability and toughness |

Hardness

M390

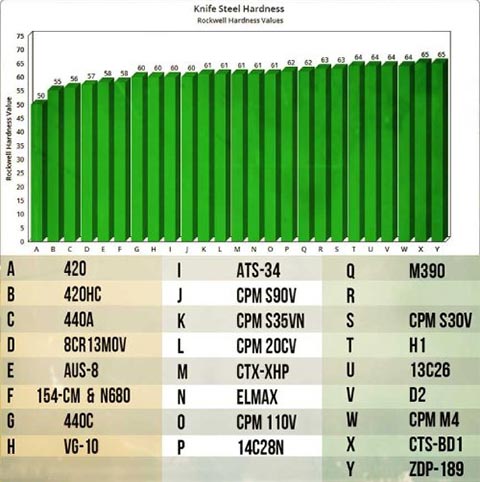

According to the Rockwell hardness score, the M390 has the upper hand.

This super steel slightly outperforms its US-crucible-industry-made counterparts, mainly because of the added Silicon and Manganese.

With a Rockwell hardness score of 60-62HRC, the M390 takes the lead.

This high hardness also comes with superior wear resistance, outstanding toughness, and excellent edge retention.

20CV

Even with a slightly lower score on the Rockwell hardness test, the 20CV super steel offers remarkable performance.

With a score of 58-61 HRC on the Rockwell “C” scale, the 20CV offers a “sweet spot” where all the best qualities of a high-end knife are present.

Wear resistance

M390

Both blade steels perform similarly here.

A higher concentration of Vanadium creates Vanadium carbides in the steel which provide better wear resistance than the Chromium carbide found in most traditional steels.

The M390 is basically the European version of the CPM 20CV super steel.

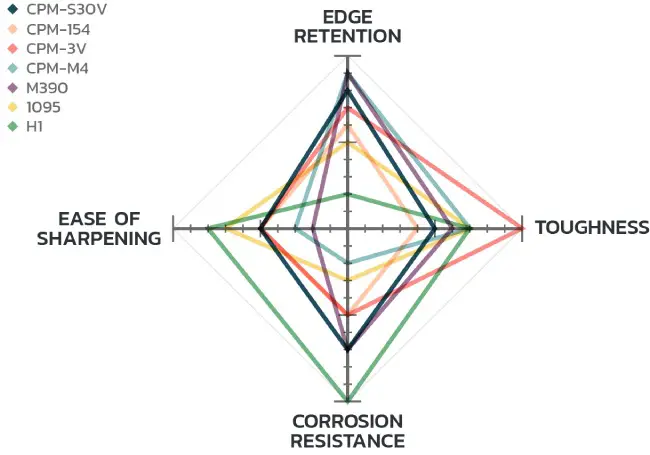

Except for some minor differences, both the M390 and the 20CV offer similar performance in corrosion/wear resistance, sharpness retention, and grindability.

20CV

The 20CV is known for its exceptional wear resistance and is extremely popular among the top knife manufacturers in the US.

leading brands like Benchmade, Kershaw, and Zero Tolerance offer this steel for its amazing wear-resistant capabilities.

As a result, knives made from the 20CV super steel are known to be extremely durable and can withstand a lot of rough uses.

Edge retention

M390

The higher volume of Vanadium and Chromium used in the steel; combined with an advanced heat tempering technology, provides amazing-quality edge retention over time.

Usually, edge retention capabilities are closely related to hardness and the M390 offers both.

20CV

The competition gets only fiercer as the CPM 20CV is not the one to give up so easily.

This super steel also offers impeccable edge retention and is known across the globe for retaining its sharpness for a long time.

Alloy materials like Molybdenum and Tungsten in the composition allow your 20CV steel blades to retain their sharpness even after a long time any normal knife would fall out of the competition.

Toughness

M390

One of the few sectors in which the M390 has a noticeable lead over the CPM 20CV is toughness.

The chipping resistance of the M390 is higher than most other premium steels, even those with the same Rockwell hardness score.

Even if the M390 steel isn’t the toughest out there, it clearly takes the lean in our today’s head-to-head comparison.

20CV

The CPM 20CV loses the lead on toughness to its European counterpart. However, the toughness of the 20CV is no joke either.

This super steel introduces more than enough toughness to your blades so you can enjoy a long-lasting service.

Usually, a blade has to balance hardness, corrosion resistance, and toughness.

Unlike most traditional blades, the CPM 20CV doesn’t offer hardness and corrosion resistance by sacrificing toughness. It provides balanced performance in all aspects.

Grindability

M390

The M390 also takes the lead here. Most blade steels offer extreme durability and edge retention, which also makes them harder to sharpen.

A decent amount of Chromium carbide inside allows the M390 to be surprisingly easier to sharpen.

The Chromium carbide is softer than the commonly used aluminum oxide sharpening belts. As a result, grinding your blades will be comparatively easier with the M390.

20CV

Despite being just as strong and durable as the M390, the 20CV lacks sharpening ability.

A lower concentration of Chromium carbide formed in the process may make the CPM 20CV more durable and wear-resistant, but it also makes the steel harder to grind.

The only good news is that you won’t need to sharpen your blades every now and then.

Once sharpened properly, your blade will be able to hold its shape and sharpness for a long time.

Corrosion Resistance

M390

This round also ends up in a tie as both today’s super steel perform closely in terms of corrosion resistance.

They both are capable enough to withstand the harshest of weather, including rough saltwater and extremely humid environments.

The M390 also has a trace amount of Manganese and Silicon, which increases the corrosion resistance and tensile strength.

20CV

The CPM 20CV offers similar performance to the M390 in terms of corrosion resistance.

The higher amount of Chromium used creates a protective chromium oxide film that protects the steel from the environment, the elements, and corrosion.

As a result, CPM 20CV knives are extremely corrosion-resistant and can be used in harsh weather conditions like salt water and humid environments.

Price

M390

The M390 is a bit costlier than the 20CV. This steel is primarily used to make high-end custom knives.

The exceptional hardness, edge retention, and wear/corrosion resistance make the M390 the best steel to make knives.

You can get your hand on a decent quality M390 knife for around $300-500. However, the price ranges from $120 all the way up to $5600.

20CV

With more affordability, the CPM 20CV takes the lead here on this M390 vs 20CV debate. Even after offering a similar performance to the M390, the 20CV comes at a much more affordable price range.

The price ranges usually from $150-$400 and can be a better option, considering the price.

20CV vs M390: Which one to choose?

The M390 is essentially the European version of the CPM 20CV.

With similar performance in edge retention, corrosion resistance, and grindability; both these premium steels will be your perfect EDC companion for a long time.

However, the M390 performs better in toughness but comes at a really high price.

In comparison, the 20CV offers almost identical performance well within a very reasonable price.

If you long for high performance in a cheaper price range, the CPM 20CV will be the best option for you when thinking about M390 vs 20CV.

On the other hand, if you prefer superior toughness and cool aesthetics, the M390 will be your best bet.

FAQs

1. Is M390 steel good for knives?

Ans: Yes, the M390 is incredibly popular across the globe for knife making. The advanced PM engineering technology helps the steel develop amazing wear resistance, excellent edge retention, and superb corrosion resistance, which is perfect for high-end knives.

2. Is 20CV better than M390?

Ans: Not necessarily. After edge geometry, heat treatment is the deciding factor that determines if 20CV will be better than M390 and vice versa. In other words, the manufacturer’s heat treatment approach makes the difference in their quality, not these steels’ chemical compositions since they’re the same.

3. How good is M390?

Ans: This mainly depends on how skilled you are with knives and how often you use them. M390 is highly corrosion resistant with a fine-tuned edge but requires utmost care.

Leave a Comment